Not all stringed instruments are intended to be loud. Some instruments were developed in a context where music was performed for the private enjoyment of the influential few, whether in courtly ceremonies or aristocratic dinner parties. However, there must always have been outdoor music requiring loud instruments, and over the last couple of centuries the development of public concerts and large concert halls has motivated evolution of instruments to make them louder and louder.

For a plucked or struck instrument, there is a balancing act to be performed. For a given amount of energy put into the string by the player, you can either let it leak out to the body quickly or slowly. This leakage rate is determined entirely by the magnitude of the scaled admittance, as was shown in section 5.1.2. The plot of this scaled admittance from the previous section, comparing three different instruments, is reproduced here for convenience. Compare the results for the guitar and the banjo. The curve for the banjo lies well above the one for the guitar, over virtually the entire frequency range. The banjo will be louder (no surprise there), and it will inevitably have a sound that dies away quickly because the energy is used up fast. If a long sustain is wanted, to allow long legato lines, loudness must be sacrificed. To get both, there must be a lot of energy in the string in the first place: this is the background to the evolution of the modern piano, with strings so heavy and tight that players ordinarily use mechanical assistance (from the piano mechanism) to excite them: they don’t play with their fingernails like a guitarist. Some specific information about piano strings and their impedance will be given in section 12.2.

Bowed instruments are different: the scaled admittance still governs the rate at which energy is extracted from the string into the body, but now the player is constantly feeding energy back into the string with their bow. The trade-off between loudness and sustain does not apply: a bowed note can be sustained as long as the player’s bow arm permits. The different designs of the violin and the guitar have come about to exploit this key difference.

Compare the curves for the violin and guitar in Fig. 1. At the lowest frequencies, a few strong resonances of the guitar produce peaks higher than the corresponding low-frequency peaks of the violin. (The reason that the violin cannot tolerate peaks as high as those of the guitar lies in a phenomenon of bowed-string instruments called the wolf note: we will come back to this in section 9.4.) But at higher frequencies, from about semitone 24 on the axis scale here, the violin curve rises steadily above the guitar curve. By semitone 40 or so, it reaches very similar levels to the banjo. This suggests that the violin has been designed to extract energy quickly from the string in this higher-frequency range, allowing it to be quite loud. We will find out in section 5.3 about a particular feature of the design of the violin, that is mainly responsible for this strong divergence from the behaviour of the guitar. But no-one chooses a pizzicato violin to play legato lines of the kind possible on the classical guitar or the harp.

We will return yet again to this plot and the comparison between these three instruments in section 5.3. But before that we digress a little to enquire what, if anything, an instrument maker might do to increase loudness, and what are the associated hazards and pitfalls. If the energy from the string is to ‘leak’ into the body more rapidly, strings must be chosen with the highest possible wave impedance, while the admittance of the body must be made as large as possible. In other words, you want to put heavier and heavier strings on lighter and lighter instruments. The limit on that process might be set by the sound getting too loud, but usually something else goes wrong first: the structure of the instrument body fails under the stress of the string tensions.

Instrument designers need to exercise ingenuity to get round this problem. One extreme example is the modern piano. Unlike earlier instruments like the harpsichord, a substantial metal frame is used to carry the string tensions, separate from the wooden soundboard that serves to convert the energy from the vibrating string into sound. Piano strings have become extremely heavy as well: indeed, the typical strings of a modern concert grand are not what you would ordinarily call ‘string’ at all: imagine trying to tie a parcel with piano wire 1 mm in diameter.

The violin gives an example that is less extreme, but arguably more ingenious. A number of features of the violin play a role in helping to withstand the string tension. That is not to say that this is the only reason for these design features: as in other highly-evolved designs, many details manage to fulfill multiple functions. But for the moment we will concentrate on this aspect. First, it is useful to see how far down the line of “making it louder” the violin has been pushed. The total tension of a typical set of violin strings is around 20 kg (or around 200 N). The strings turn over the bridge through an angle around $25^\circ$, resulting in a downbearing force on the violin’s top plate around 10 kg. That much weight is supported on a panel of softwood that may be less than 3 mm thick.

Figure 2 highlights a few features of the violin that help it withstand the stresses. Number 1 is rather general: notice that all the component parts of the violin body are curved in some way, rather than flat. The top and back plates are arched, the thin pieces of maple forming the ribs are curved. As is familiar from structures like bridges, an arch is much better than a flat beam or panel when it comes to withstanding a downwards load. We already know the reason for this, from the discussion in section 3.2 of curved shells compared to flat plates. A flat plate can only resist loading through bending, but a curved shell automatically brings in forces of compression or tension. This tends to make it stiffer: recall the discussion of corrugated roofing panels.

Feature number 2 directs attention to the shape of the f-holes. In common with many other stringed instruments, the violin body has “sound holes” in order to create a Helmholtz resonance. As discussed in section 4.2, this produces an extra resonance at low frequency to help the bass response of the instrument, and also improves the sound radiation efficiency of low modes of the body.

Less obviously, there are advantages in the violin having slot-shaped holes. The slots create a rather flexible “island” between the holes, exactly where the bridge sits, and we will see in section 5.3 that this flexibility is implicated in a major difference in acoustical behaviour between the violin and the guitar. But putting slots close to the bridge is dangerous. If simple rectangular slots were used, the sharp corners would create stress concentrations, and cracks would soon form in the softwood of the top plate, starting from these corners. To minimise this problem, both ends of the slot are curved over, avoiding the sharp corner. There are two choices: you could bend both ends the same way, producing C-holes as seen in some earlier instruments like viols, or you bend the two ends in opposite directions, producing the familiar f-holes of the violin.

Feature number 3 shows two blue rectangles, indicating two important structures inside a violin, the soundpost and bassbar. These have an important acoustical consequence, described briefly in section 5.1 (see Fig. 3), but they also help with the problem of withstanding the stress from the strings. The downbearing force is transmitted through the feet of the bridge, so that placing a reinforcing beam under one foot and a supporting pillar near the other will obviously help.

Feature number 4 is the purfling around the edge of the top and back plates. The black lines of the purfling are not painted on (except in very cheap mass-produced instruments): instead, a three-layer sandwich of dark-light-dark wood is inlaid into a slot painstakingly cut around the edges of the plates. Purfling has an important aesthetic effect, and violin-makers put a lot of effort into making it look just right. But this apparently decorative feature of the violin also serves a practical function. The edges of a violin, especially on the top plate, are vulnerable to being knocked, which can start a crack running in from the edge. Inlaying strips of wood across the grain close to the edge gives some protection against this.

The features numbered 5 and 6 go together. Some of the most famous and valuable violins are several centuries old already. Despite the best efforts of their makers, most of them have suffered damage during that time. But these instruments look in good condition, and are still being played regularly. They have all been repaired over the years, and there are two features of the construction that have allowed repairs to be effected without leaving eye-catching scars. When a violin maker has to make a major repair, they will remove the top plate to open the box up. This can be done without causing much damage because the box is held together with gelatin-based animal glue which is strong enough, but slightly less strong than the surrounding wood. A violin repairer can remove a top plate by carefully inserting a flat-bladed knife like a table knife into the glue layer, and working it around the edge to crack the joint apart. (The label in Fig. 1 marks the joint of the back plate rather than the top plate, simply because it is more easily seen in the picture. But it is very rare to remove a back plate: nearly all repairs of this kind involve the top plate.)

Having done the repair, the top plate will be glued back on. Another ingenious feature is now revealed. Even with care and skill, the act of opening a joint like this will probably cause some damage, so that the joint does not fit back together quite as snugly as was originally the case. But look again at Fig. 2: the plates fit to the ribs with overhanging edges, so that the glue joint is in a rather dark and obscure corner. So a tiny amount of damage near this joint will not show as much as it would have done without that overhang. An instrument like the lute does not have this feature. Just as with the violin, it is occasionally necessary to open up a lute for maintenance, but it is very much harder to remove the top plate and effect an invisible replacement.

Finally, feature 7 is another very general one, and it brings us back to our original question, “Can you make it louder?”. It concerns the choice of material out of which the violin is made. Material choice is an important topic, and what we have to say next is relevant to many stringed instruments, not just to the violin. A simple argument based on making an instrument as loud as possible can be used to derive a criterion for selecting material. This criterion is widely used by instrument makers: but I suspect that they often do not remember that it is based on such a crude objective.

Violins, and most other stringed instruments, are ordinarily made of wood: in particular, top plates or soundboards are usually made of spruce or cedar of some kind. If a violin-like instrument were to be invented today, would wood be the obvious choice of material, given the huge range of artificial materials now available? We can use the criterion of loudness to develop a simple index of merit, then use an intuitively-appealing graphical method developed by Ashby [1] to survey the whole gamut of available materials, to see what would make the best choice by maximising that index of merit.

Within the limitations of the super-crude approach we are using here, we already know what is needed to make a louder instrument: we want to maximise the typical level of the bridge admittance. We can suppose that the length and width of the instrument body are fixed (being governed by tradition and the ergonomics of playing), but that the plate thickness might need to be varied depending on the material. This thickness will be governed by a requirement that the vibration resonances occur at roughly the usual frequencies — any big deviation from the norm is likely to produce an instrument which doesn’t “sound like a violin”. It is not realistic to hope to fix all the individual resonant frequencies, but it is easy to ensure that the average spacing of modes has the correct value. The details are described in the next link.

The conclusion is that we want to choose the material that maximises a certain index of merit. It goes under various names in the literature (such as “radiation ratio”), and it can be written in several different forms. One form that is commonly seen is the ratio of the speed of sound to the density (see the previous link for details). This form is relevant to instrument makers because of the availability of a commercial measuring instrument called a “Lucchi meter”, which allows the speed of sound in a billet of wood to be measured directly.

For the purpose of the Ashby argument, we need to write the index of merit in a different form, as a combination of stiffness and density. If we were only dealing with isotropic materials (ones like metals with the same properties in all directions), the combination would be $E/\rho^3$, where $E$ is Young’s modulus and $\rho$ is density. (The Greek letter $\rho$ is pronounced “rho”: for some reason, it is the conventional symbol used to denote density.) There is a complication that we will come back to in a moment, but first we can meet Ashby’s ingenious approach. In this problem, as in many other questions about material choice in engineering design, the index of merit we want to maximise takes the form of a product of powers of the material properties: in this case $E$ and $\rho$. There is an easy graphical way to visualise any such combination.

The first step is to gather up those two properties of every material, and combine them in a plot like Fig. 3. Each particular material would appear as a dot in this plot, or more commonly as a small blob because the properties of any given type of material are always somewhat variable. Blobs are marked for materials like “steels”, “diamond”, and “Nylon”. These are grouped within larger blobs, outlined with thicker lines, gathering classes of material together: metal alloys, ceramics, plastics, foams, and so on. Logarithmic scales are used on both axes, because $E$ and $\rho$ both range over several orders of magnitude.

But this log-log scale does more than that: a straight line with slope 3, like the two slanting red lines shown in the figure, will automatically join materials that share the same value of $E/\rho^3$. (The mathematical reason is that $E/\rho^3=K$ means that $\log E -3 \log \rho = \log K$, which is the equation of a straight line of slope 3.) So, for example, the right-hand red line suggests that soundboards made of lead and of silicone rubber would give equally loud violins. Neither of those materials sounds very promising, and that is because they fall towards the right-hand side of the plot. To maximise our index of merit, we want to push the slanting line as far to the left as we can, as indicated by the arrow.

What do we find, as the left-most materials? We find the region for woods, parallel to the grain. The next-best material falls in the top left of the blob for composite materials: specifically, the label “CFRP”, standing for carbon-fibre reinforced plastic. So soundboards should probably still be made of wood, with the second choice falling to a carbon-fibre composite of some kind. This is very reassuring: wood is indeed what most instruments use, but there are some commercially-available instruments (especially guitars) using a “sandwich” construction involving a light core material with a layer of carbon fibre on each side.

But we need to come back to the snag mentioned earlier. Wood is not an isotropic material: the stiffness of wood is usually significantly different in the grain direction, compared to any cross-grain direction. The chart in Fig. 3 acknowledges this: there are two blobs for the wood data, showing each individual type both parallel and perpendicular to the grain. Our index of merit needs to combine both these stiffnesses, and as was explained in the previous link a natural choice would fall mid-way between these two blobs on the logarithmic scale. Figure 4 shows a close-up of the plot, just showing the data for woods, and including an indication of this intermediate region.

The plot indicates that the very best material for a soundboard would be balsa wood. If loudness were the only criterion, this is probably a correct deduction. Indeed, some balsa violins have been made, and they work well. However, balsa is so lightweight that it raises other issues, particularly of robustness. The material is simply too fragile to withstand the rigours of a typical violin’s life. Instead, violin makers typically opt for carefully selected spruce, which combines a reasonable value of our merit index with a reasonable degree of robustness.

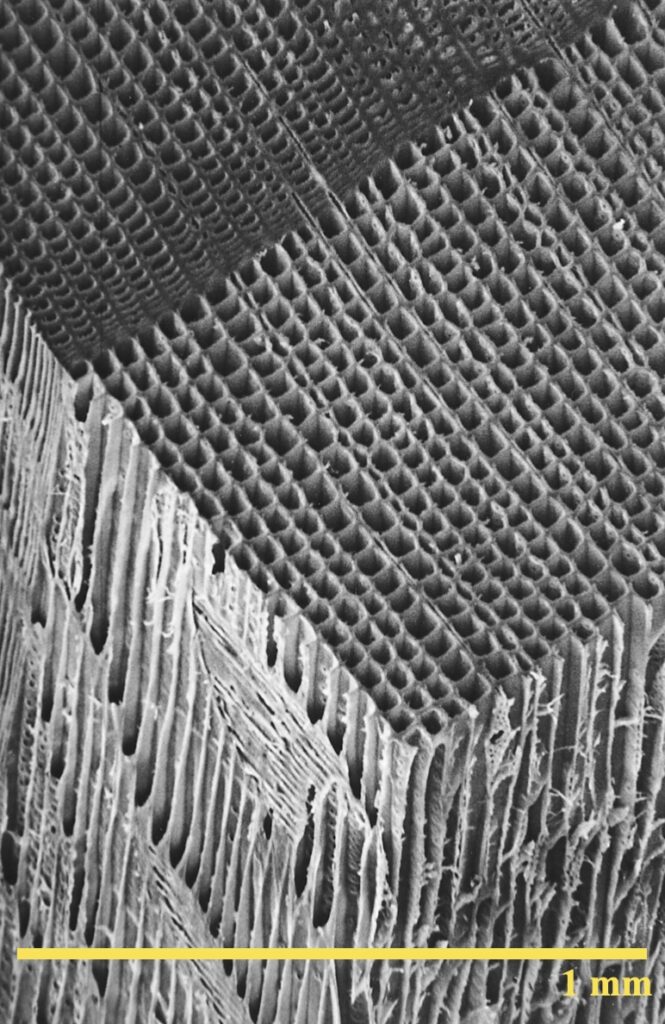

Looking back at Fig. 3, you might be wondering why wood has such extreme properties, compared to the wide range of man-made materials. To see the reason, we need to put a piece of soundboard-quality spruce under the scanning electron microscope to see its microstructure. Figure 5 shows a typical example: you can see a lot more micrographs of wood structure in section 10.2.1. A softwood like Norway spruce (Picea abies) consists mainly of cells called tracheids, which are long, thin-walled tubes running vertically in the tree. It consists mainly of empty space, in fact. The structure is rather like a box of drinking straws. This kind of structure is very efficient for reducing density while preserving a good level of stiffness, exactly the combination needed to put the material into an extreme position in the Ashby plot.

There are indeed man-made materials with a similar structure: the most common are various kinds of hexagonal honeycomb structure, used as the core material in doors or in the floor panels of aeroplanes. The difference is that in these materials, the “cells” are of centimetre scale, whereas wood cells are about three orders of magnitude smaller. This small size is what allows wood to be treated as a homogeneous material, able to be carved into complicated shapes like the top of a violin. As technologies like 3D printing develop, it is becoming feasible to make materials with microstrucure approaching this fine scale: perhaps in a few years we will be able to print artificial wood, or indeed complete violin tops.

[1] Michael F. Ashby; “Materials selection in mechanical design”, Butterworth-Heinemann (Fourth edition 2011).